By some strange quirk of fate, I

spent almost two years living in a place called Vrededorp. This is a run-down

suburb of central Johannesburg a short walk from Wits (University of the

Witwatersrand)

I had been searching for a room to rent as a mature

student and stumbled across this one. It was a strange area, historically

restricted to poor whites, it had become a "grey area" where the

apartheid rules were not enforced. If Google Earth is any guide it hasn't come

up in the world in the 30+ years that have elapsed since then.

I was rather shocked to see such poverty and

degradation among whites, something you never saw in Zimbabwe at the time.

There were while alcoholics sleeping rough in the park. One froze to death

while I was there. South Africa has long been a country of deep contrasts,

complexities and contradictions.

There were small shacks with corrugated iron walls. I

couldn't find these on street view. At least they seem to have been

"upgraded" in some ad-hoc way.

I did find snapshots to remind me of the journey to

campus, on foot at first, then later using a second hand bicycle. The "Red

Jesus" church whose raucous Afrikaans hymns drifted into my room every

Sunday. The atrium of the students union where I picked up that card for Vrededorp

lodgings. The ramshackle shops at the traffic lights where I turned into

"coolie town" as it was labelled on some old maps. I always admired

the old red school building with its hints at classicism. That was a marker

that I was almost home.

My fellow students were nearly all white and there were

only a couple who didn't have cars. I was living on a very strict budget.

Strange to be so closely allied to poverty while I had a comfortable home with

a swimming pool and three young children back in Zimbabwe. We wrote almost

every week, and visited three times a year. How I longed for those visits.

How ironic that Zimbabwe felt like heaven and South

Africa a deeply broken country in those distant times. Joburg has become a

refuge for so many young Zimbabweans, just as Dubai has been for me. Sadly I

think South Africa has still to pass through its "Zimbabwe moment" I

don't think I will live to see the brighter days that southern Africa surely

deserves.

But I do see bright glimmers of hope. Physical poverty

is one thing. Poverty of the soul another.

I wonder if anyone has ever done a

study of Dutch Reformed Church buildings in Southern Africa. I was always

impressed by the architectural quality of the ones I stumbled across when I was

living in that part of the world.

I lived in Harare for twenty years during the

optimistic period of independence. This little church on Samora Machel Avenue,

tucked in behind an office building, is a real gem. I was able to take shots

from unusual angles while supervising construction of Century Towers. Sadly I

never went inside. You could say that this was "Cape Dutch" I

suppose, but to me it branches out into more original territory.

The proportions are pushed to the limit, but in a good

way and the three dimensional plasticity of the form reminds me a little of

Bavarian baroque, which I studied a little many years ago.

The second example is in Vrededorp, where I stayed for almost two years, more than 30 years ago. The location is very dramatic, perched on a cliff edge. These shots are from Google Earth. No smart phones or digital cameras in those days. More conventional Cape Dutch styling here, but still a very adventurous and confident massing.

I would love to know more about the architects involved and the various strands of design development within the church, regionally. I'm sure there will be examples in Namibia, possibly Botswana also, certainly several in Zimbabwe and potentially dozens across South Africa. Are there parallel traditions in Holland? Does anyone still work in this tradition? Are they protected in any way?

Lots of questions. Maybe the church struggles with its apartheid demons. But the buildings are part of our heritage, and a very positive contribution to the public domain in my view.

I have lived close to gasworks and

/or gasometers several times in my life and they always held a certain

fascination. Quite extraordinary structures, especially the ones with dark

Victorian overtones. And they move.

There were two large storage drums close by when I

lived in Wincobank in Sheffield, close to the Tinsley viaduct. At one time I

tried to keep a record of their movements, rising and falling in response to

supply and demand. These days I guess you could do a time-lapse video. Imagine

cars, people and clouds scuttering madly about while the giant cylinders float

serenely up and down.

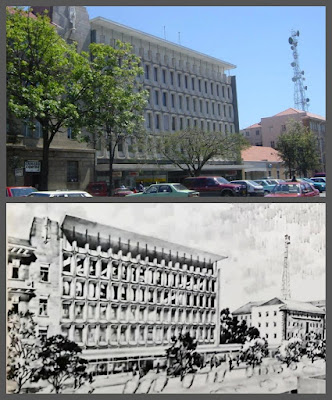

The pencil sketch is from my pocket notebook of the

Wincobank era. The painting below is my dad's. He was an art teacher, former

policeman, loved to paint industrial landscapes. That was inspiration to me of

course. The enlightenment romantics had a notion of the sublime. Beauty that

borders on terror.

The other gasworks is just down the hill from my old

room in Vrededorp. I had forgotten about it. I'm impressed that they haven't

demolished all the older structures with their dramatic scale and geometry.

Must be a heritage thing. I can't imagine that they are all still functional.